Tools & Equipment Needed

To be properly prepared to splice a polywire electric fence, try to have the following items available:

- Gritted Crimping Sleeves (at least three per splice)

- Crimper Tool

- Gloves

- Voltage tester

- An extra length of extra poly wire (in case you need to completely replace a portion)

How to Splice PolyWire

If you want a strong, permanent splice, then a crimping sleeve splice is a must. To do this splice you should:

- Turn off the power to the fence.

- Use a voltage tester to make sure the power is off.

- Wearing gloves, slide three crimping sleeves over one end of the polywire.

- Holding the sleeves on the first polywire, slide the second poly wire through the open slots on the sleeves.

- Using your crimper tool, squeeze each of the sleeves tight to create a strong connection.

- Test the strength of the sleeves by pulling on each end to see if the polywire slides out. If it does slip, use the crimping tool again.

- Turn on the power to the fence.

- Use the voltage tester to check voltage levels on each side of the splice. If one side is significantly lower, you’re not getting a good connection and may need to redo the splice.

Why Are Splices Needed?

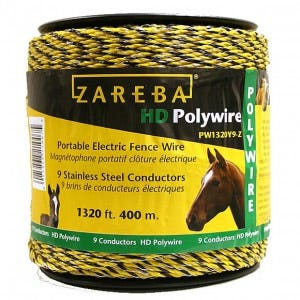

Splices are required on electric fencing for two reasons. The main reason you need to make polywire splices is to extend a fence’s length. Without splicing, you won’t be able to entirely protect and seal off a paddock. Splices are usually needed as you come to the end of one spool of electric poly wire, but you still need to extend the fence. They allow you to link the polywire from one spool to the next.

Secondly, polywire sometimes breaks and the de-energized section of fencing needs to be quickly re-established. Creating a splice is the best way to do that. Polywire can snap for a number or reasons, including:

- Falling objects.

Zareba Voltage Tester - Vehicle intrusion.

- Stress applied by fenced-in livestock.

- Stress applied by wild animals from outside the fence.

Why Do PolyWire Splices Work?

Poly wire is usually spliced with a group of Crimping Sleeves which are available in packs of 25. These metal fittings are conductive, and designed to re-establish an electric connection between two pieces of polywire.

They do so by locking the two sides together and allowing the polywire’s conductors to touch. The direct contact re-establishes the electrical connection.

The polywires are held in place by the clamping action created by the crimping sleeves. To establish a secure and safe connection, at least three crimping sleeves should be used per splice. As the sleeves are squeezed closed, the sleeve grips the polywire and creates the necessary electrical connection.

Crimping Sleeves are also used to secure polywire to an end post on a fence line.

Simple Knotted Splices

If you don’t have crimping sleeves or a crimping tool immediately available, a temporary solution is to simply tie the two ends of the polywire together.

Doing so with multiple knots will re-establish an electrical connection between the two sides of electric fencing.

Be warned, though, knotting your polywire should only be used as temporary fix. Your knots may slip or break if they’re tested by your livestock.

How Do You Splice PolyWire?

Do you feel prepared to splice polywire on your own? If you have any questions, don’t hesitate to call our customer service line at 855-5-ZAREBA or contact us online.

We would also love to hear about your fencing efforts the next time you visit Zareba® on Facebook. Feel free to leave us a message there, share a picture or join in the conversation.

You can also subscribe to our E-Newsletter for the latest deals from Zareba® as well as articles on livestock and livestock control.