Installing Electric Fence Wire

Running and Securing Wire

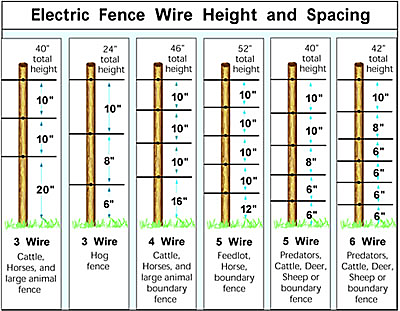

The height, spacing, and number of the wires necessary will vary with the animal you are containing and purpose of the fence. Wires can be run from the coil or roll using a payout spinner or, a multi-wire fencer, if running multiple strands.

Crimping sleeves and/or appropriate knots are used to secure wires to corner, end, and gate posts. Wire should be strung on the inside of line posts and on the outside of curves.

Electrified wire will require insulators for fastening to posts. The type of insulator that you choose will be dependent upon the type of post and wire that you are using, as well as your specific fencing needs.

For non-electrified wire, staples or clips will suffice. If driving staples into wood posts, do so at a slight diagonal so they straddle the wood grain. This spreads the legs of the staple, increasing holding power. Drive staples at upward angles for downhill grades and downward angles for uphill grades. Be sure not to drive too deeply as the wire must still be able to slide through the staples for adjusting tension.

Have questions about what wire will work best for your fence? Check out of wire guide for more information.

Note: The required wire spacing will vary with the species / class of animal(s) being contained or excluded. See the Animal Selector section for recommendations by animal.

Tensioning Wire

The amount of weight needed to tension wire will depend on the type of wire chosen. High-tensile wire is typically tensioned to approximately 200-250 pounds. Be sure you do not apply too much tension to wires, as excessive tension will damage wire and may lift fence posts out of the ground in low spots.

You can use a ratchet in-line strainer or tightener to tension wires. You could also use our Electrobraid® Tension Kit to make sure you have all the tools needed for the job. Ratchets will also allow you to adjust wire tension for temperature changes. Use a tension indicator spring to adjust each wire to the proper tension. Next, you will tighten the rest of the wires by feel to match the tension on the wire with the spring.

Note: Wear heavy gloves and eye protection when tensioning wire to protect from possible injury.

For short stretches of fence line (<600 feet), the in-line strainer and tension indicator spring, known as the friction center, can be placed anywhere. On long, fairly straight runs, it is more ideal to place them in the middle so that tension is dispersed equally to both sides of the fence. Long runs with both straight and curving sections should have the friction center placed in the bends section rather than the straight section.